Case Study Demonstrating Time & Resource Savings Using A2P2

Background

A global medical device manufacturer sought to reassess the ageing behaviour of a sterile barrier packaging system made from two polymeric components:

Component A: A rigid medical-grade polymer tray

Component B: A flexible medical grade sealing film

Traditional ageing plans followed a conservative Q10 = 2 assumption per legacy interpretations of ASTM F1980. This resulted in:

Long ageing campaigns (12–18 months)

High use of climatic chambers, samples, and technician time

Premature classification of some products as “failing” due to over-severe test conditions

The manufacturer wanted to improve scientific confidence, reduce validation time, and establish realistic shelf-life derived from polymer behaviour rather than convention.

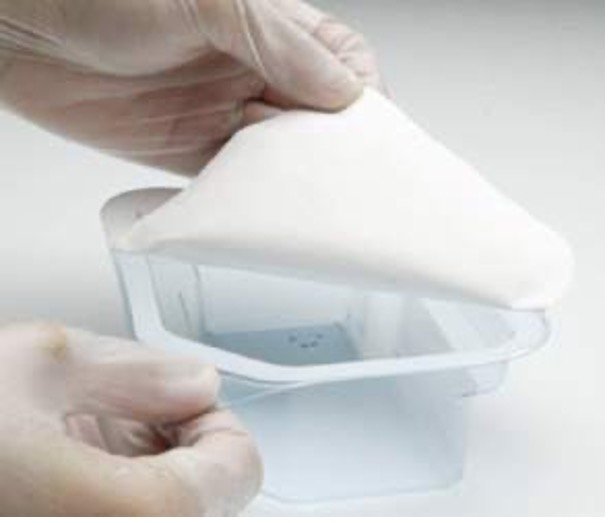

Figure. Medical device tray (Component A) with flexible sealing film (Component B) used in ageing evaluation.

A2P2 Approach

Using A2P2’s DMA, TTS, and DSC workflow:

Quantified physical ageing behaviour (the dominant mechanism for most medical polymers).

Extracted Q10 and Ea values for each component independently.

Identified substantial differences:

Component A: Q10 ≈ 11

Component B: Q10 ≈ 5

Calculated a median Q10 = 7 for the assembled product (following A2P2 methodology).

Ran mechanical performance assessments (modulus, Tg, peel strength, impact resistance) before and after ageing.

Results

1. Significant Reduction in Ageing Time

Using Q10 = 7 instead of the default Q10 = 2 drastically shortened the required ageing time.

Traditional ageing (Q10 = 2):

~13.1 months at 45 °C → equivalent to 345 years real-time ageing.A2P2-derived ageing (Q10 = 7):

Required only 0.4 months at 45 °C to simulate the same real-time duration.

Total time saved: 12.7 months (≈95% reduction).

This reduction allowed the team to complete validation in weeks instead of a year, accelerating internal decision-making and design lock-ins.

2. Reduced Laboratory Resource Use

By shortening the ageing plan:

Climatic chamber occupancy dropped by >90%

Technician hours reduced (fewer interim pulls, less documentation)

Sample consumption decreased significantly

Test variability reduced because ageing conditions were aligned with the true physical ageing mechanism, not artificial over-severe oxidation conditions

3. Improved Understanding of Material Integrity

A2P2’s polymer-specific analysis revealed:

Component A exhibited excellent long-term stability, maintaining modulus and impact resistance beyond 4 years simulated ageing.

Component B, though chemically similar, had a different physical ageing rate due to processing-related molecular orientation (validated with DSC/TTS results).

Peel strength of the overall assembly remained stable and showed no ageing-dependent decline.

This confirmed the packaging system was more robust than previously assumed under legacy Q10 = 2 ageing plans.

Strategic Value to the Manufacturer

✔ Faster Product Release

Validation timeline reduced by almost one full year.

✔ Lower Risk of False Failures

Avoided incorrectly failing stable products due to outdated oxidation-only models.

✔ Evidence-Based Shelf-Life Extension

The rigid component demonstrated performance well past 4 years, enabling longer storage and more resilient supply chains.

✔ Materials Ageing Library Initiated

The manufacturer began establishing component-specific Q10 and Ea values — a foundation for:

More accurate future ageing studies

Better material selection

Faster ECO/PCN approval cycles

Streamlined regulatory submissions

Regulatory Alignment

A2P2 outputs and methodologies align with:

ISO 11607 stability testing requirements

ASTM F1980 principles, including revisions related to mechanism-specific Q10 use (Dr. Nazli Ozdemir is the ambassador for ASTM F1980)

AAMI TIR17 recommendations for aging rationale and model selection

The approach strengthens—not complicates—regulatory defensibility.

Sustainability Impact

Reduced chamber energy consumption

Fewer wasted samples

Less need for redundant testing

Less rework and fewer scrap materials across validation cycles

Aging programs become faster, lighter, and more environmentally efficient.

Conclusion

This case study demonstrates how A2P2 transforms accelerated aging from slow, conservative, oxidation-centric assumptions into a mechanism-driven, data-rich validation workflow.

Time saved: ~12.7 months

Chamber use reduced: >90%

Scientific confidence increased: material-specific Q10 and Ea

Regulatory readiness enhanced: stronger evidence and clearer rationale

A2P2 enables manufacturers to reach accurate shelf-life conclusions rapidly, reduce validation risk, and build a more resilient and efficient aging strategy.

Case Study: Extending Tubing Lifespan Beyond Manufacturer's 1-Year Recommendation

Challenge

The manufacturer recommended replacing the biopharmaceutical tubing every 12 months, likely to drive frequent purchases. This short lifespan led to high replacement costs and production downtime.

Solution

We optimised cleaning methods, added mandatory drying, conducted monthly inspections to extend lifespan.

Results

Tubing lifespan reached 28.5 months (137.5% improvement), maintaining safe performance under operational conditions.

Benefits

Cost Efficiency: Reduced replacement frequency, cutting expenses.

Enhanced Productivity: Less downtime increased output.

Improved Safety: Regular inspections minimized failure risks.

Sustainability: Longer-lasting tubing reduced waste.

Case Study: Extending Medical Device Tray Lifespan with Rapid FDA-Approved Aging Studies

Challenge

Our medical device trays, made of copolyester with a composite film and adhesive, had a manufacturer-recommended 5-year shelf life, leading to frequent replacements and high costs. Traditional aging studies, taking years, were too slow to optimise material selection and predict long-term performance.

## Solution

We implemented an FDA-approved accelerated aging study, calculating aging rates and activation energies for the copolyester tray, composite film, and adhesive junction in weeks, compared to years for traditional methods. We evaluated various copolyester formulations for durability under simulated long-term conditions.

Results

The tray assembly lifespan extended to beyond the manufacturer recommendation, maintaining structural and adhesive integrity in accelerated tests completed in just weeks (as opposed to industry standard taking years)

Benefits

- Cost Efficiency: Reduced replacement frequency, cutting costs.

- Time Savings: Accelerated studies enabled rapid material optimization.

- Reliability: Ensured tray stability for extended use.

- Sustainability: Longer lifespan minimised waste.

Conclusion

Using FDA-recognised accelerated aging, completed in weeks, we extended our medical device tray lifespan to 6 years, enhancing reliability, reducing costs, and promoting sustainability.

Here are some critical products we have defined useful lifespan for.

GULSINE NICHE EXPERTISE IS TO QUICKLY AND PRECISELY UNDERSTAND HOW PRODUCTS / MATERIALS WILL BEHAVE IN THE LONGER TERM AND WHETHER IF THE INTENDED LIFESPAN IS SUITABLE FOR THE CRITICAL PRODUCT.

You synthesised a new biopolymer and you would like to compare it against synthetic counterparts.

GULSINE is happy to test one sample for free and demonstrate it over A2P2 for academic institutions.